01 The Final Beneficiary – Coal Mining Industry in South Africa

The hardcore advantages of GK two mass subresonance technology are fully demonstrated in the South African coal washing industry. It has significantly increased production efficiency and reduced operating costs.

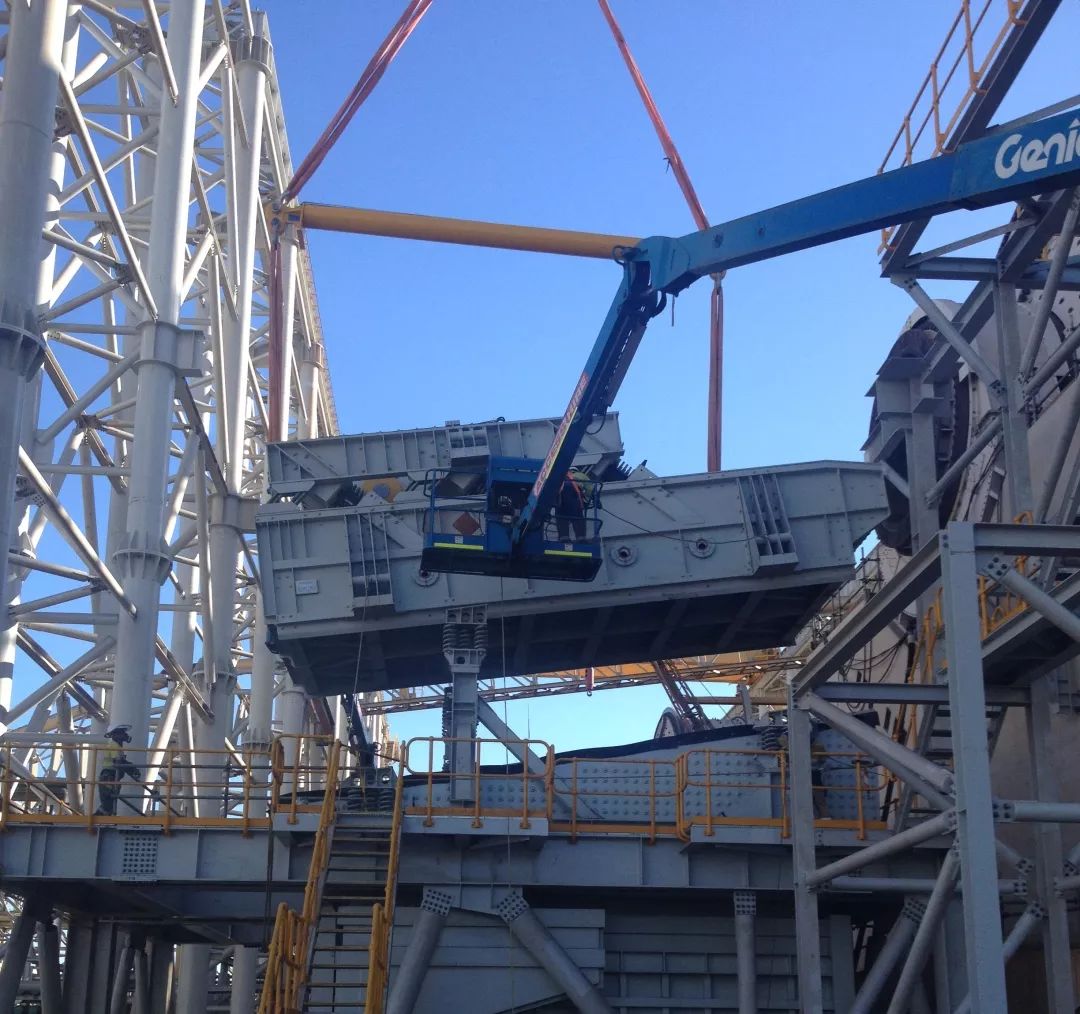

General Kinematics (USA), through its African partner IMS Engineering, entered the local coal mining industry for the first time.

Davide Gado, General Manager of GK, said that they are working to change the screening method in the coal industry.

02 Industry Leader in Crushing and Separation Technology and Solutions

Since March 2018, the two companies have formally cooperated. Since then, IMS – the industry leader in crushing, separation technology and solutions has begun the development of screening technologies in the African market .

The two companies have the same values, powerful technology and business culture to reach a cooperative relationship, says Davide Gado. The cooperation will both fill the missing products in the IMS crushing system and better improve the solution.

“In 2019, we are confident of delivering the first orders for GK screens in the South African coal industry. Not only to change the outlook of the African coal industry, more importantly, but we will also draw on our reputation, our performance in terms of the Australian and Asian coal industries, and provide proven solutions as a breakthrough to officially enter the African coal industry.” Davide Gado says.

03 The Core Technology of GK Screen

The core technology of GK screen is two mass vibration, which utilizes one mass (vibration exciter) to drive another mass (screen body) as the vibration method for the vibration equipment. The drive with one or more vibration motors is mounted on the vibration exciter. The vibration exciter is connected by an excitation spring and assembled to the screen. The combined two masses and the spring constitute a subresonance system with responsiveness. The system can actively respond to load changes without typical load damping effects of traditional brute force screening technology.

GK screens have produced tangible benefits for many global users. With excellent customized engineering capabilities in development and design, GK vibration equipment can be installed on the existing foundation. Compared with the traditional screening efficiency, GK screen can process up to 30% more materials. This is of great value to the coal industry in South African, where most of the equipment is too old and overloaded, resulting in short life, inefficient screening and high maintenance costs.

GK screen can reduce the energy consumption by two thirds compared with the traditional vibrating screen, and the energy consumption is less when it is operating at the same or higher production capacity. The benefits brought to our customers have been demonstrated in many cases and public platforms, and have been recognized by our customers.

04 Customer Comments

A coal industry customer in Australia of GK published a technical paper in 2018 demonstrating the advantages of GK screens and improvements to customer sites. The customer commented: “GK replaced a 4.2m wide vibrating screen with a 3.6m GK screen, the customer’s production increased by 30% and electricity consumption was also saved.

The amplitude of the GK screen is very constant and the material is “rubbed” evenly on the screen plate rather than sliding. While improving the screening efficiency, the loss of screen plate is also reduced. Under the same working conditions, the loss rate of GK screen plate is much lower than that of traditional vibrating screen plate.

05 Advantages and Characteristics of GK Screens

Compared with traditional banana screen, the materials stay on the GK screen surface three to four times longer. “The GK screen is the leader in screening and dewatering technology.”

At the same time, the vibration force borne by the structure and screen is lower than that of the brute force screen, making the GK screen highly reliable. It distributes mechanical forces along the width and length of the machine and eliminates potential stress points, basically causing no equipment damage.

To sum up the above advantages, there is less maintenance demand for a GK screen. In addition to regular replacement of screen plate, only maintenance and service of the vibration motor and spring are required.

GK currently has the largest vibrating screen manufactured, with the dimensions of 5.4m wide and 8.5m long.

Engineering design of the GK screen has also been completed. It is up to 6.6m wide and 10m long (composed of various modules) with a capacity up to 2600 T/h of material (Note: depending on the particle size, unit weight and treatment process of the material).

The double-mass vibration technology of the GK screen is world-leading, bringing customers world-class experience value!、

(April 23, 2019)